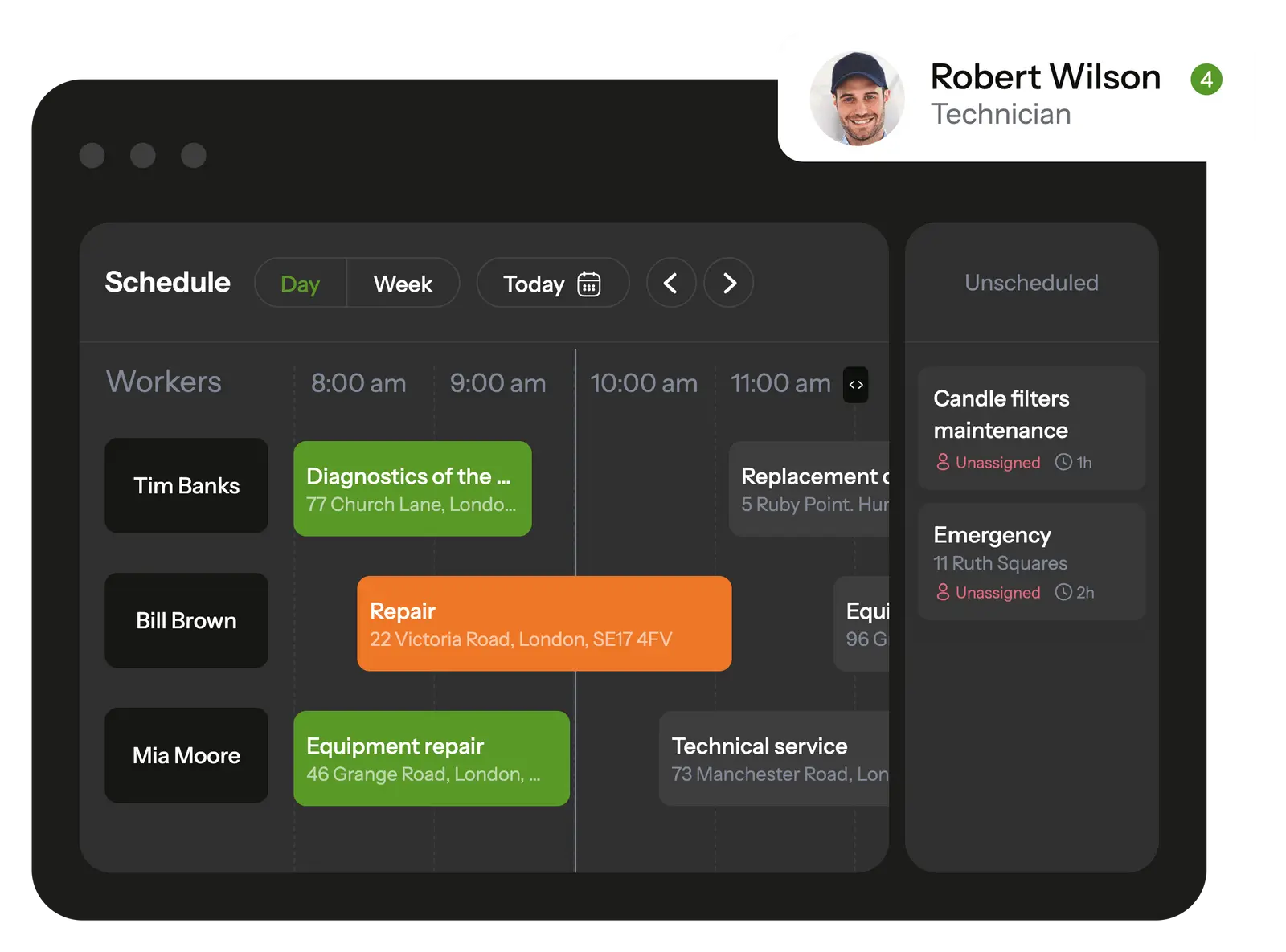

Planado simplifies task management and allows you to control your work schedule in just a few clicks:

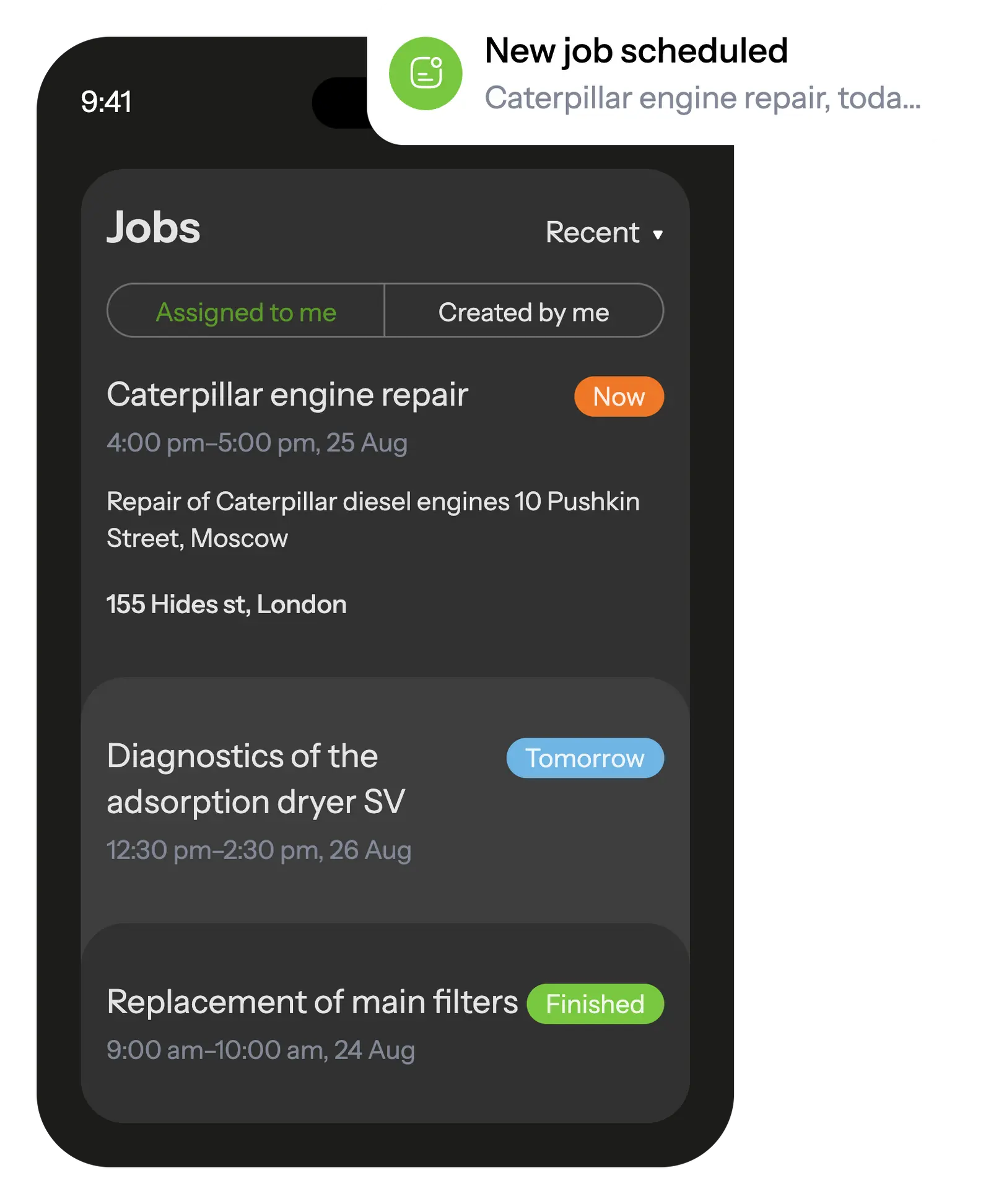

In the mobile app, employees can see information about scheduled work and receive notifications about new tasks.

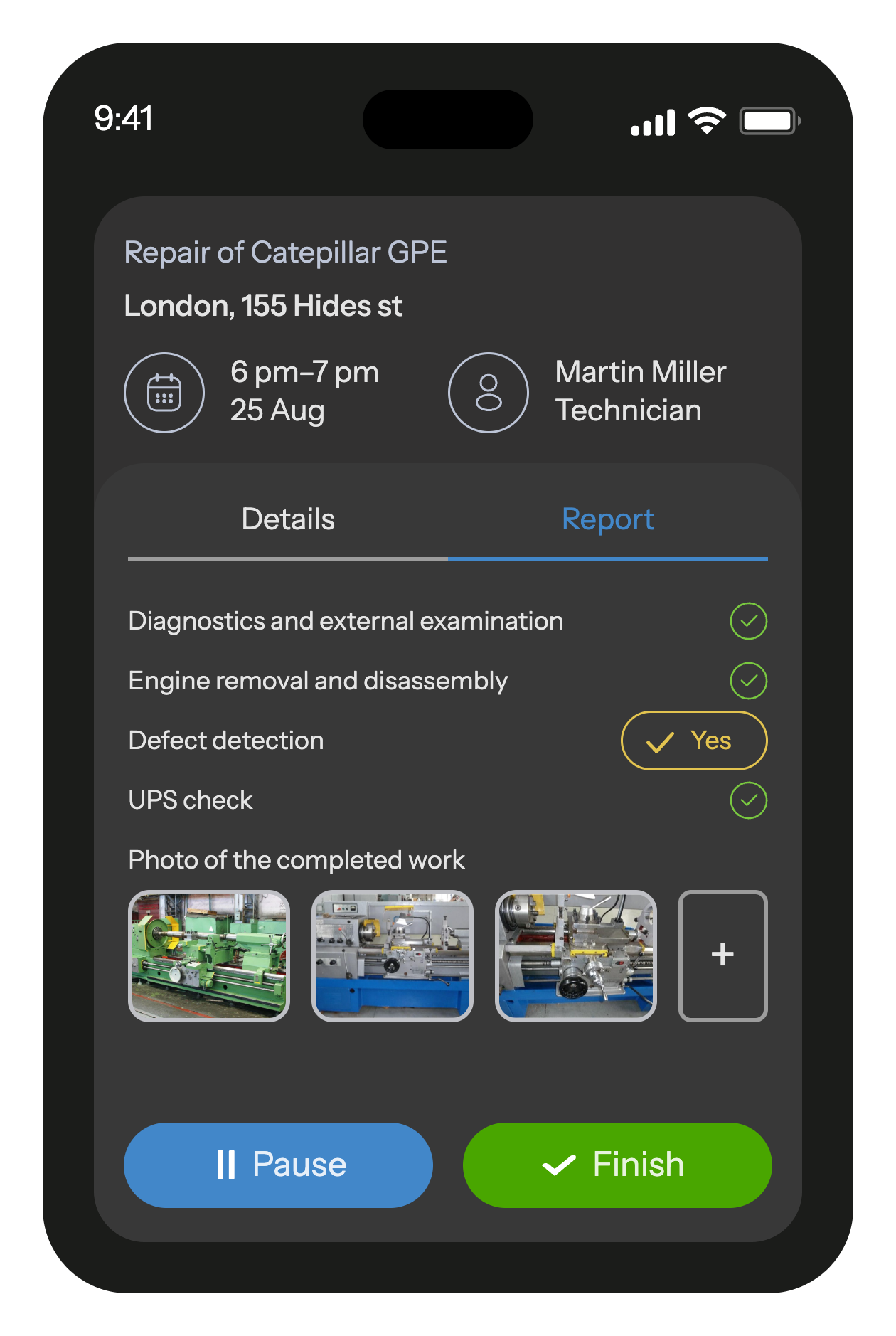

Thanks to built-in checklists, specialists will not miss a single task from their to-do list.

Upon completion of the work, the employee fills out a customizable report with photos and other data, which is instantly saved and sent to the office.

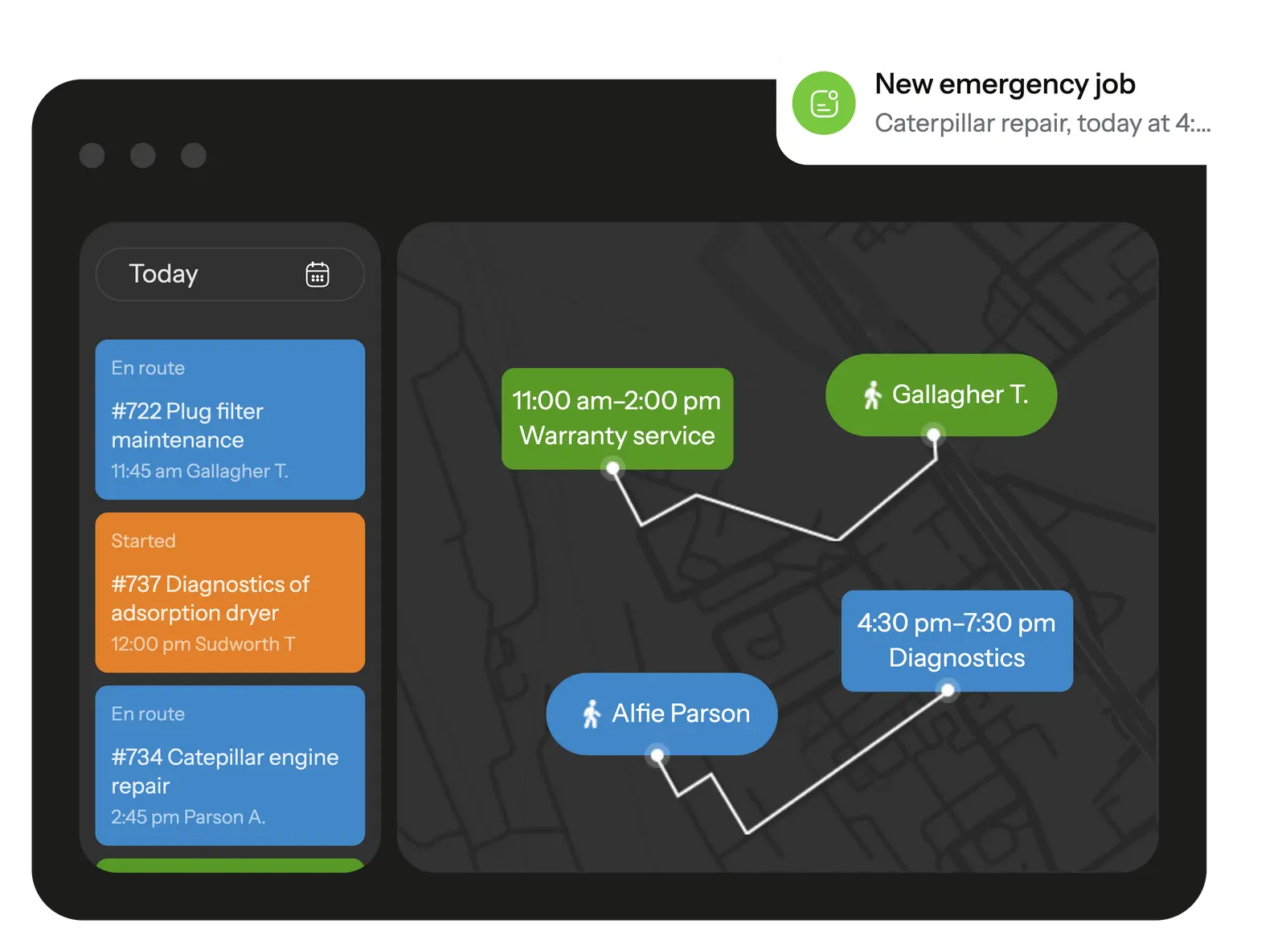

Track the location of field specialists during working hours, dynamically assign tasks based on their proximity, and access work and movement logs at any time.

GPS monitoring helps calculate mileage and assign the nearest employee to urgent work.

At the beginning of each task, employees receive a detailed checklist to avoid mistakes and complete all the work.

Upon completion of the work, they fill out a report with photos and text, recording and saving all important data that may be useful in the event of warranty claims or follow-up work.

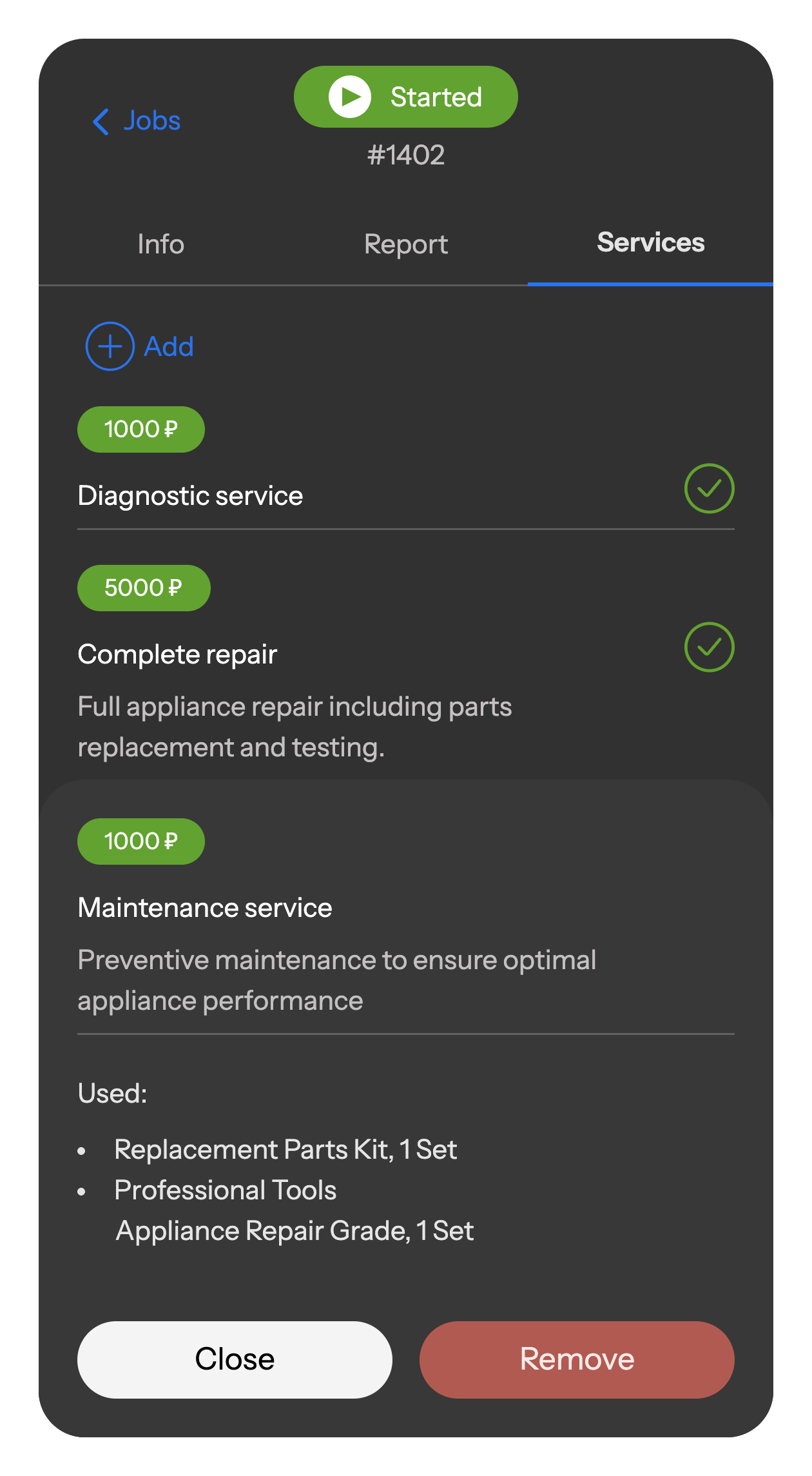

The employee records all completed work and materials used in the mobile app, which are saved in the report and automatically transferred to the office and warehouse.

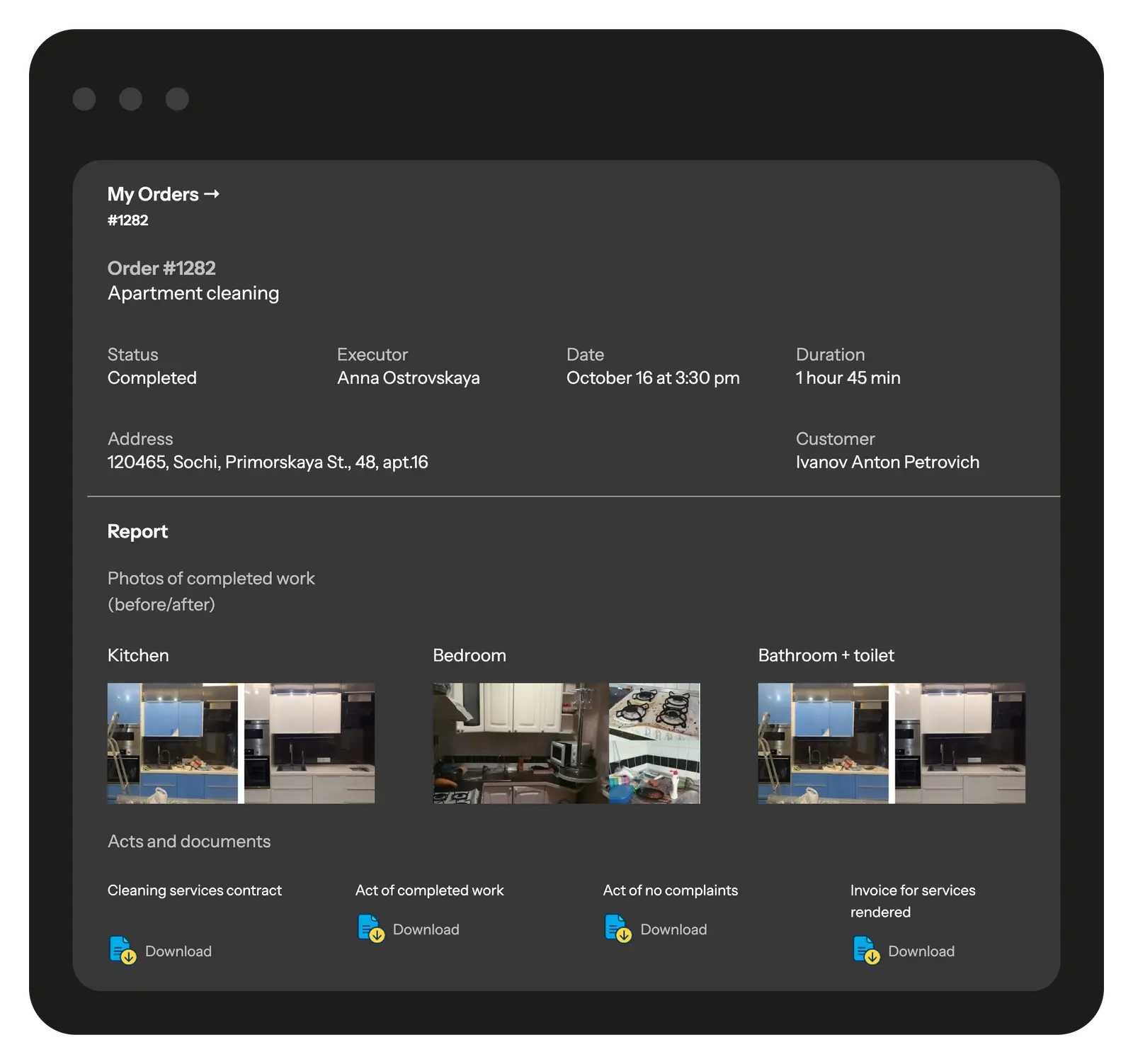

Give your customers access to a branded page with complete information about repair and service requests, work stages, photo reports, and technical documentation. Through the customer portal, your customers can track the status of their requests, view completed and planned work, and leave feedback on the quality of service. You decide which requests, objects, and details will be available for the customer to view.

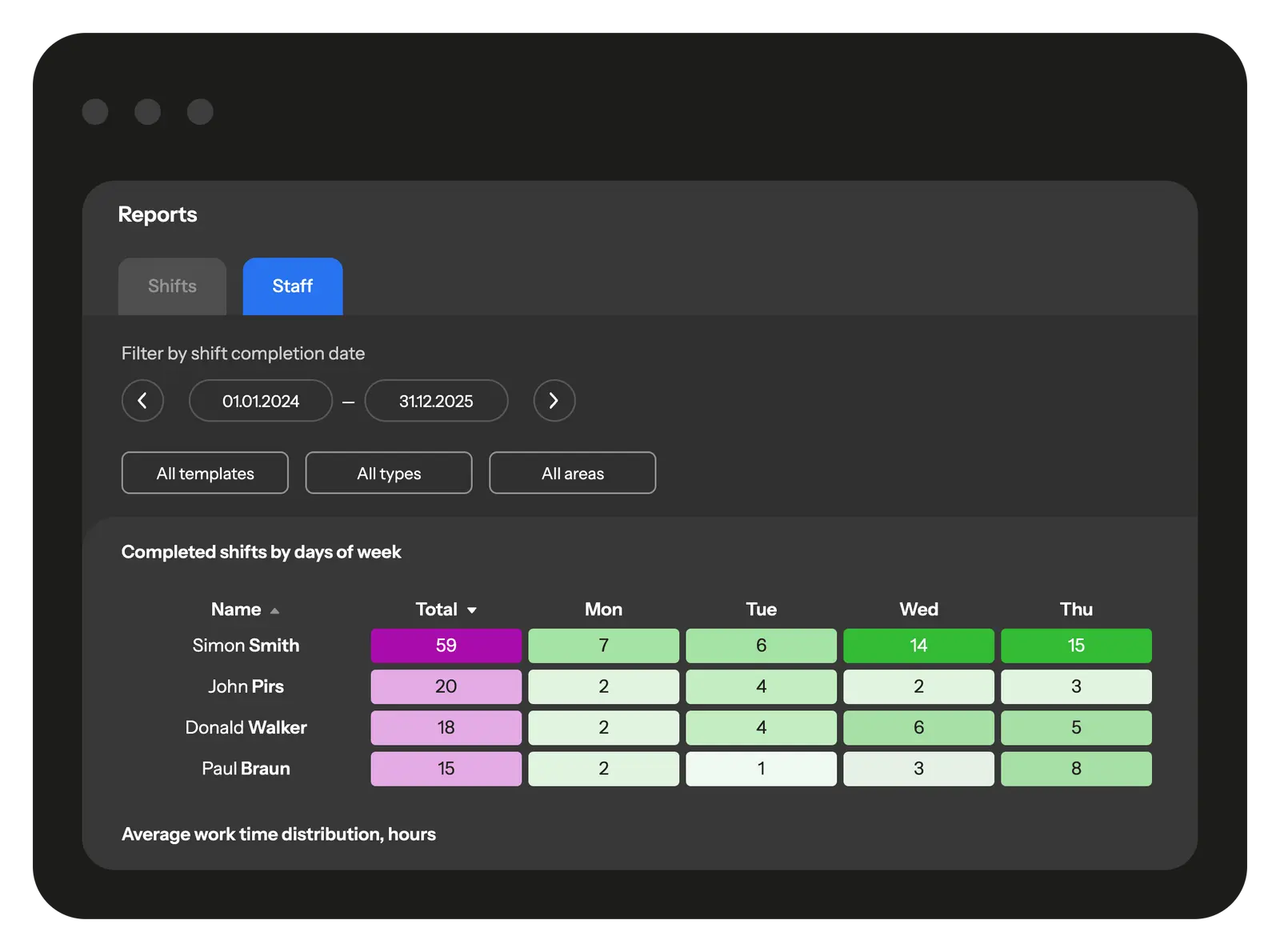

The Reports page contains statistics on your Planado jobs and contractors. Here you can assess the volume of completed and planned work, see the reasons for failures, and view contractor performance.

Planado easily adapts to the specifics of companies servicing industrial equipment

Create your own templates for requests, reports, and statements.

Engineers cannot close a request until they have completed all the required steps.

Equipment types, consumables used, service stages, departure times, responsible engineers, and details for each object.

Connect Planado to 1C, CRM, warehouse, and accounting for complete automation of work and accounting

No. Implementation is fast and straightforward — most companies start using Planado within 2–3 business days. Our specialists help with setup, onboarding, and staff training to ensure a seamless transition.

Yes! Planado is fully customizable. You can create request templates, preventive maintenance schedules, and technical checklists tailored to your company’s specific workflows and compliance requirements. All settings are available through a convenient interface — no programming needed.

All data is securely stored on encrypted cloud servers with regular backups. Access to information is controlled through role-based permissions, ensuring that only authorized personnel can view or modify data. Planado adheres to international standards for data security and industrial compliance.

Yes. Planado integrates with Salesforce, Zoho CRM, HubSpot, QuickBooks, Xero, and other systems via API. This allows you to synchronize data between departments — from maintenance logs and work orders to billing and client records — automatically.

Yes. You can register any type of equipment — from production lines and conveyors to compressors, pumps, and CNC machines. For each type, you can create individual maintenance checklists, service schedules, and operating regulations to ensure compliance with technical and safety standards.

All engineer activities are logged in Planado:

Planado is designed for flexibility. You can easily edit templates, add new services, and update maintenance standards directly in the web interface — no developer required. This makes adapting to new equipment, regulations, or workflows quick and simple.